Message From the Chairman – April 2019

March 26, 2019

Small Wonders

April 2, 2019

Marine Corrosion

Marine corrosion and electrolysis can be a confusing issue – which can cause considerable damage to your wooden boat. The solutions which may have been appropriate in the past, may not be suitable now, says marine corrosion specialist, Brian Gatt.

Wooden boats can suffer from corrosion side-effects to the timber, as well as the running gear like other boats kept in the water. The timber around metal fittings may soften and the paint starts to bubble.

Simply replacing zinc anodes may not be the best thing to do. In fact, they may be part of the problem.

Three main causes of marine corrosion in wooden boats:

- Over protection – an over-active anode, or too many anodes

- Electrical currents from articles on the boat – solar panels, engine, navigation gear, lighting, etc

-

Environmental effects – marina influences, environmental fall out or seawater conditions

Over protection by adding an overly active anode (zinc) causes the timber to become subject to alkaline degradation due to overprotection. The typical repercussions of overprotection are excessive marine growth, paint blasting on and around metallic articles plus, the added issue of alkaline degradation to the surrounding timber.

The effect of either new or old (degrading) electrical gear on a boat can be substantial. An engine, battery system, DC appliances or solar panels can potentially output DC current leakage which can cause damage to timber and/or running gear. The indicators of a stray current can be an increase in anode consumption, changes to the visual appearance of the timber or metallic articles, rapid protective coating loss and other typical signs of electrolysis – pitting, corrosion and colour changes.

Finally, where your boat is kept will make a difference to the corrosion effects on your boat. The saltiness of the water and prevailing conditions nearby can all have an effect on your boat and should be carefully considered when choose the correct protective measures for your vessel.

Are Zinc anodes right for my boat?

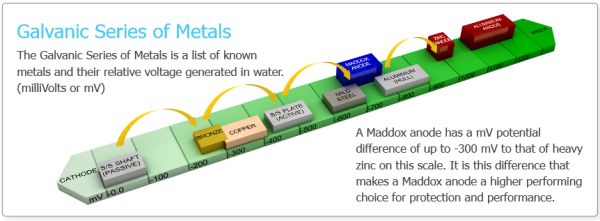

For many corrosion specialists, zinc anodes are no longer the preferred anode for wooden boats. This because they simply cause overprotection. Where timber boats require between 500 – 550mV for protection, zinc creates 950mV & aluminium 1050mV and will always overprotect a timber shaft driven vessel. The Maddox anode however, was developed in Australia for timber vessels and designed to produce a lower voltage. Whilst still providing cathodic protection against corrosion, overprotection reactions are markedly reduced when using Maddox Anodes. The improvements to anode efficiencies result in better outcomes to timber integrity, coating performance and a reduction in growth.

What to look for:

When your boat is on the hardstand – paint bubbling on timber, and timber softening around/near rudder stock and other running gear.

What to check when your boat is in the water – check in the hull around the rudder stock, prop shaft, shaft gland and any fittings connected to anodes – including any anode bolts.

How to test for the presence of an alkaline degradation process:

Vinegar test. Get some white vinegar in a spray bottle and apply around the metallic fittings. A positive reaction for alkaline change is a bubbling/frothing (like bicarb soda in water) action. If there is a positive indication, it means the timber has become alkaline and must be returned to a neutral pH.

What to do if you see evidence:

Talk to a corrosion specialist if one is nearby, or contact Brian via email on solutions@logixgroup.com.au.

Brian Gatt is a regular AWBF exhibitor.

Tim Oxley manages the AWBF Maritime Marketplace